Abrasive Blasting - Soda Blasting

Soda Blasting

Sodablasting is a mild form of abrasive blasting in which sodium bicarbonate particles are blasted against a surface using compressed air. It has a much milder abrasive effect than sandblasting.

Soda is used as an abrasive to remove paint from metals without causing depression or damaging the metal beneath the rough surface. Soda is also a great grit to use on delicate materials that may be destroyed by tougher abrasives.

Advantages of Soda Blasting

The main advantage of soda blasting is it’s a cost-efficient, single-use abrasive. Soda is water soluble making sure no abrasive remains in critical bearing areas!

- Does not harm the original surface

- Natural rust inhibitor

- Dissolves in water, creating cleaner finished product

- No pre cleaning required

- Cleans delicate materials without damage

- Cleans & deodorises

- Non toxic

- Non-hazardous food grade material

- Environmentally safe

Uses for Soda Blasting

Sodablasting is a non-destructive method for many applications

- Cleaning

- Paint removal

- Varnish stripping

- Automotive restoration

- Glass cleaning

- Ceramic cleaning

- Industrial equipment maintenance

- Graffiti removal

- Oil removal

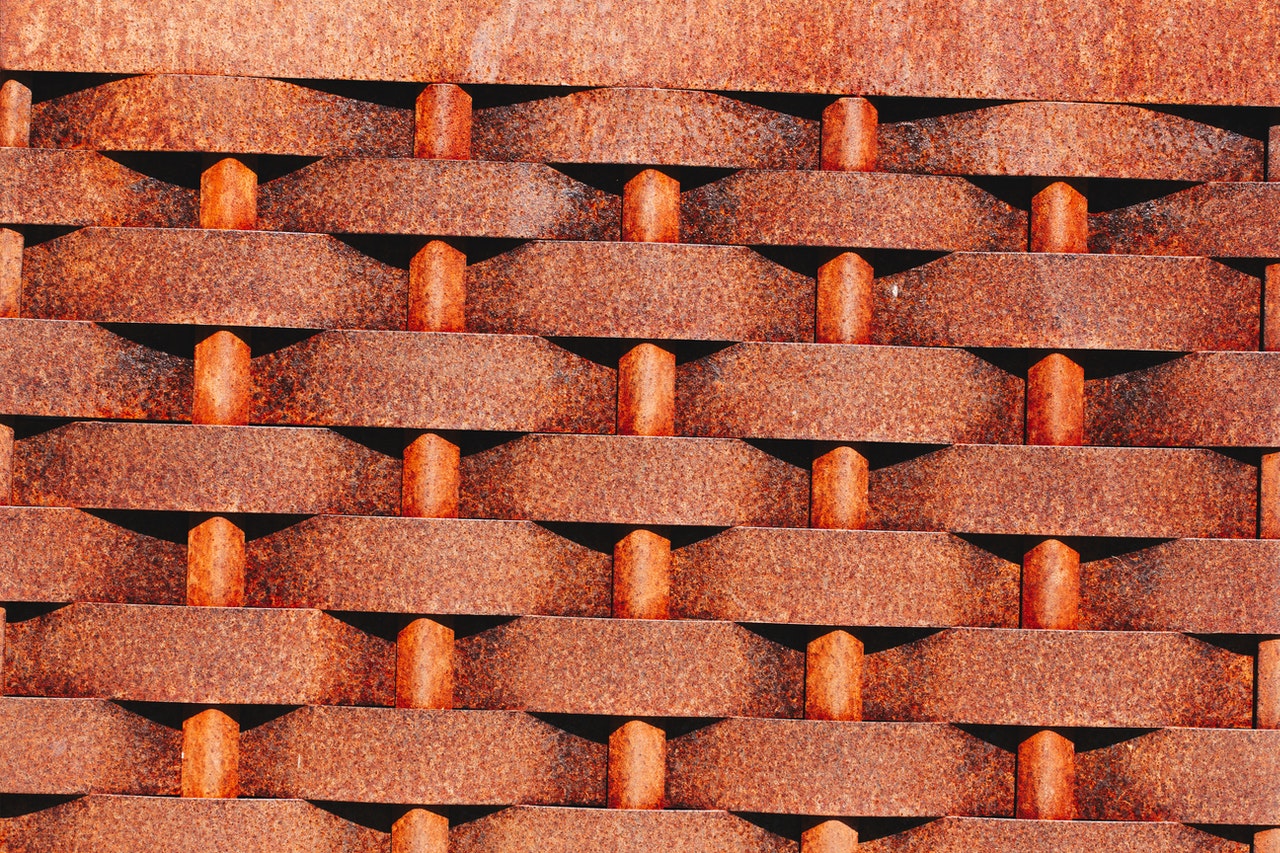

- Masonry cleaning & restoration

- Boat hull cleaning

- Food processing equipment cleaning

- Mould removal

- Smoke damage cleanup

- Timber cleaning

- Wood restoration - oak beams, oak floors, doors, stairs & banisters,