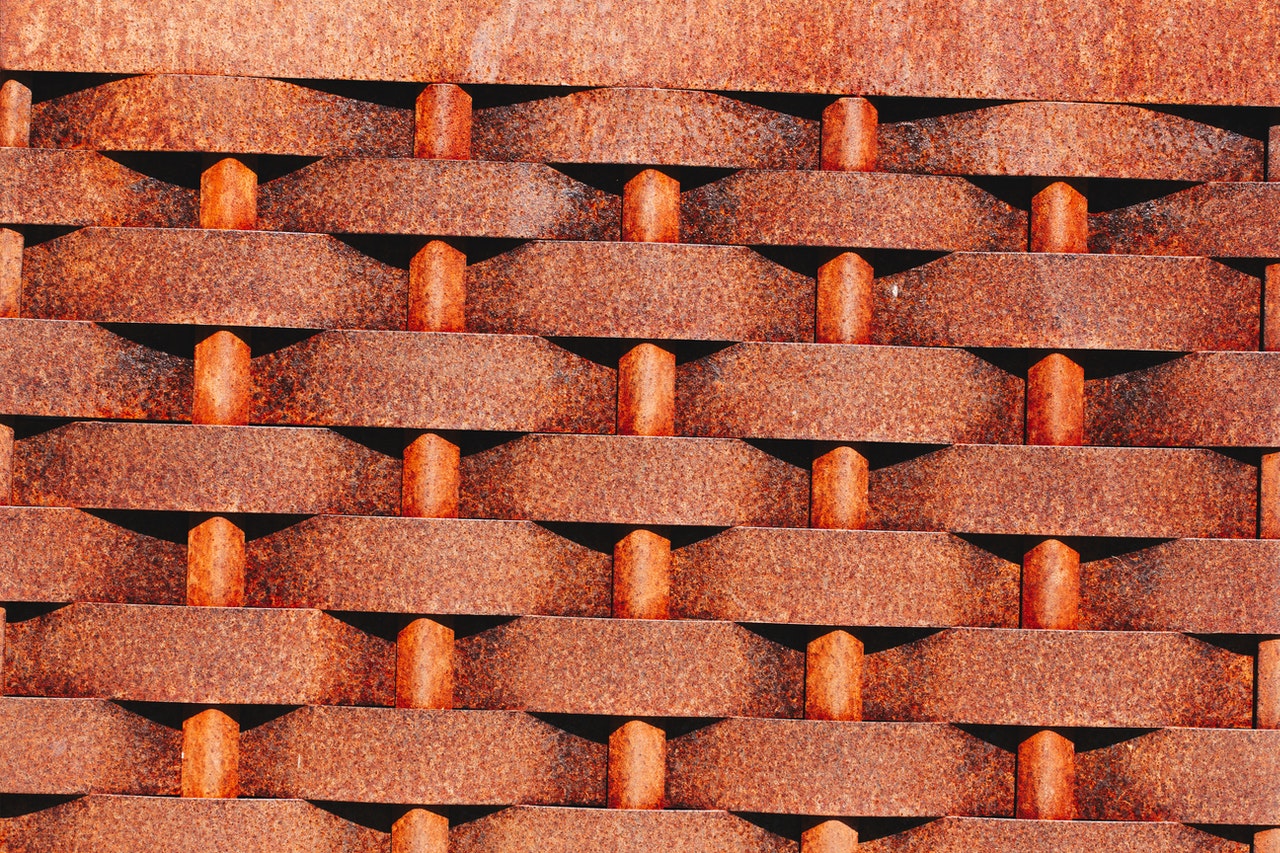

Abrasive Blasting

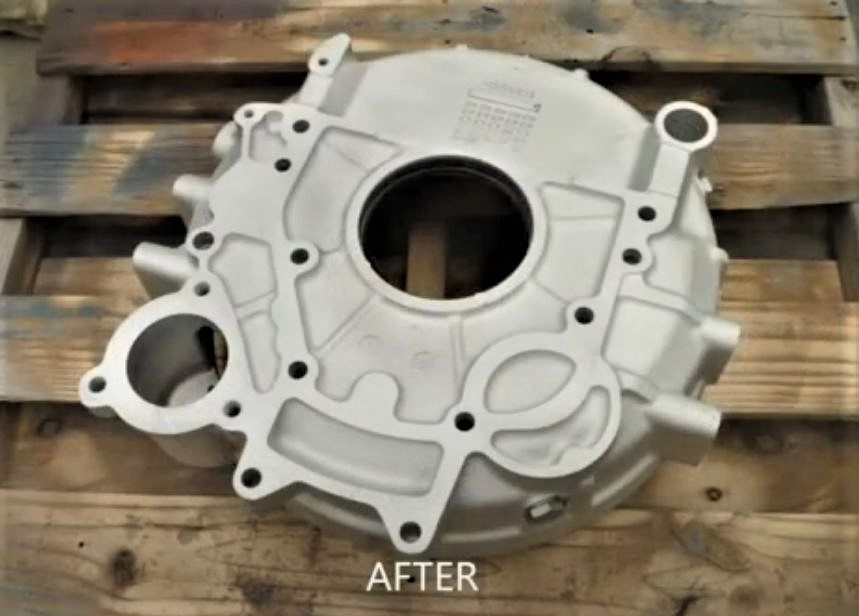

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against an objects surface under high pressure to polish a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants like corrosion, rust and old paint.

Sandblasting with silica sand was previously the most common abrasive used in abrasive blasting. Due to Occupational and Health reasons, Silica Sand is no longer used in sandblasting. There is now a selection of better and safer media used in Abrasive blasting techniques, the most commonly used is Garnet Blasting.

A protective coating is only as good as the underlying surface preparation, Absolute Blasts experienced team know which abrasive blasting technique and media will achieve coating application that lasts on your job in the harsh Western Australian conditions.

If you would like information on the different techniques and blasting media for your job call or request a quote, we are always happy to discuss your requirements or provide a free quote.

Water Blasting / Hydroblasting

Whip Blasting

Dry Blasting

Dry Blasting is a popular technique of abrasive blasting when surface cleaning or surface preparation is required. Dry Blasting is an environmentally friendly option as it does not require the use of dangerous chemicals or grinding machines.

Dry Blasting is the easiest technique in achieving a particular surface profile or required roughness.

Different types of abrasive media are used to treat an array of materials, including metals, plastics, wood, carbon fibres, glass, etc.

Dry Blasting is:-

- environmentally friendly

- time-saving

- cost-efficient

- versatile and safe technique

- replaces a wide range of solvent-based cleaning methods

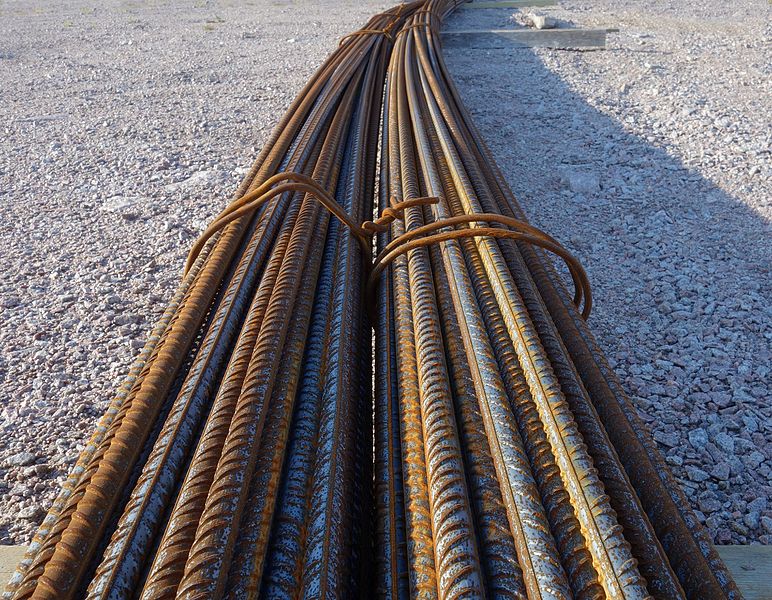

Wheelabrator

Our specially designed Wheelabrator cleans and surface-treats a variety of lengths of steel quickly and cost-effectively.

The machine throws fine steel shot at the parts using a wheel, slinging the shot into the surface and abrading the surface, cleaning it or preparing it for further surface finishing, including painting.

advantages of Absolute Blast

- Absolute Blasts team of friendly professionals guarantee a high standard of service on every job.

- Fully certified at NACE level three as a coating inspector,

- ACA Full Coating Inspector certification

- Third-level certificate in Engineering Product Systems (Blaster Coater)

- Competitive Prices

- Free Quotes

- Large easy access premises 7 acres of yard space

- 5 Speciality onsite paint booths

- Spacious sandblasting shed big enough to comfortably accommodate a semi-trailer

- Wheelabrator shed with an attached shed for priming steel, stacking, and strapping

- 6 forklift trucks for loading and unloading all types of equipment

- Jobs completed on Time & on Budget

- 25 plus years experience in Perth Sandblasting industry

Absolute Blast Services

- Garnet Blasting

- Soda Blasting

- Shot Blasting

- Grit Blasting

- Glass Bead Blasting

- Whip Blasting

- Dry Blasting

- Wheelabrator

- High-Pressure Blasting

- Degrease

- Chemically Clean

- Steam Cleaning

- Spray Painting

- Powder Coating

- Protective Coating

- High-Quality Paint finishes

- NACE Certified Inspectors

- Paint to Specification

- Primers

- Top Coats

- Wet Spray

- 2 Pac Painting