Abrasive Blasting - Grit Blasting / Shot Blasting

Grit Blasting / Shot Blasting / Wheelabrator

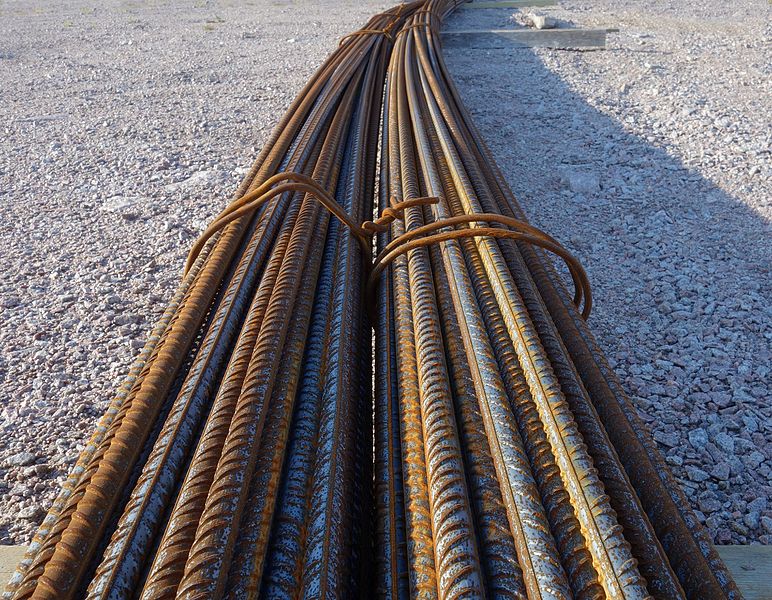

Shot Blasting or Grit Blasting uses steel grit as an abrasive in the removal of paint and rust from steel metals.

Shotblasting has an entirely different pressurizing system than sandblasting. This abrasive treatment method uses a specialised machine called a Wheelabrator similar to a spinning wheel to centrifugally accelerate shot-like material and blast it against a surface.

Advantages of Grit or Shot Blasting

Shotblasting has its place when you require deep abrasive penetration on denser materials. Where sandblasting might be too gentle and time-consuming, shot blasting will quickly prepare thick and heavy surfaces.

- High performance cleaning and descaling

- No free silica

- Environmentally friendly

- Recyclable

- Chemically inert

Uses for Shot or Grit Blasting

Shotblasting is a much more aggressive abrasive technique than sandblasting. It’s usually used for larger and more difficult preparation objects that need a strong application force and a denser media material to clean and prepare a surface.

- Peening for tough surfaces

- Deep abrasive penetration on dense materials

- Removal of caked-on rust or baked-on pollution

- Preparing metal surfaces for painting and powder-coating

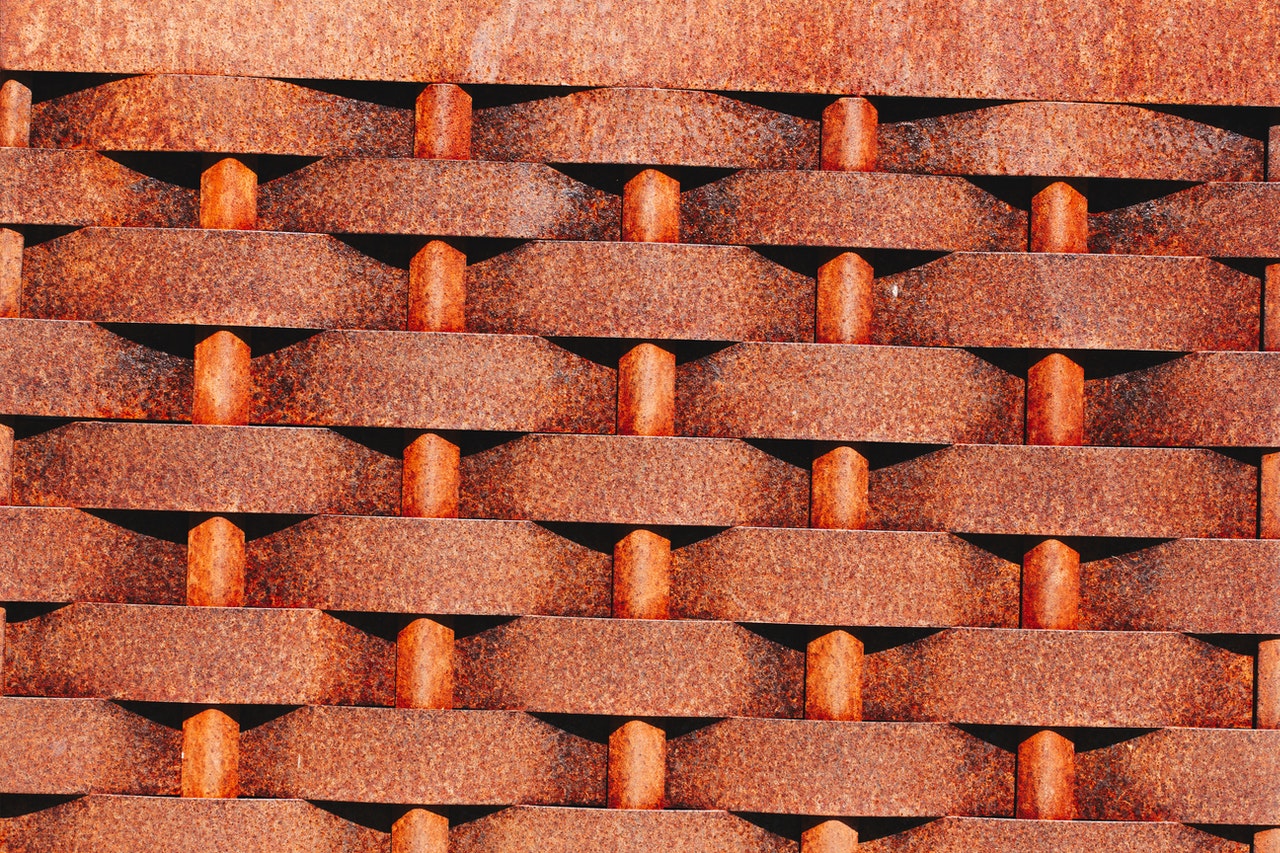

Wheelabrator

Our specially designed Wheelabrator cleans and surface-treats a variety of lengths of steel quickly and cost-effectively.

The machine throws fine steel shot at the parts using a wheel, slinging the shot into the surface and abrading the surface, cleaning it or preparing it for further surface finishing, including painting.