Abrasive Blasting - Sand Blasting

Sand Blasting

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against an objects surface under high pressure to polish a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants like corrosion, rust and old paint.

Sandblasting thoroughly cleans and prepares a surface for painting.

Advantages of Sand Blasting

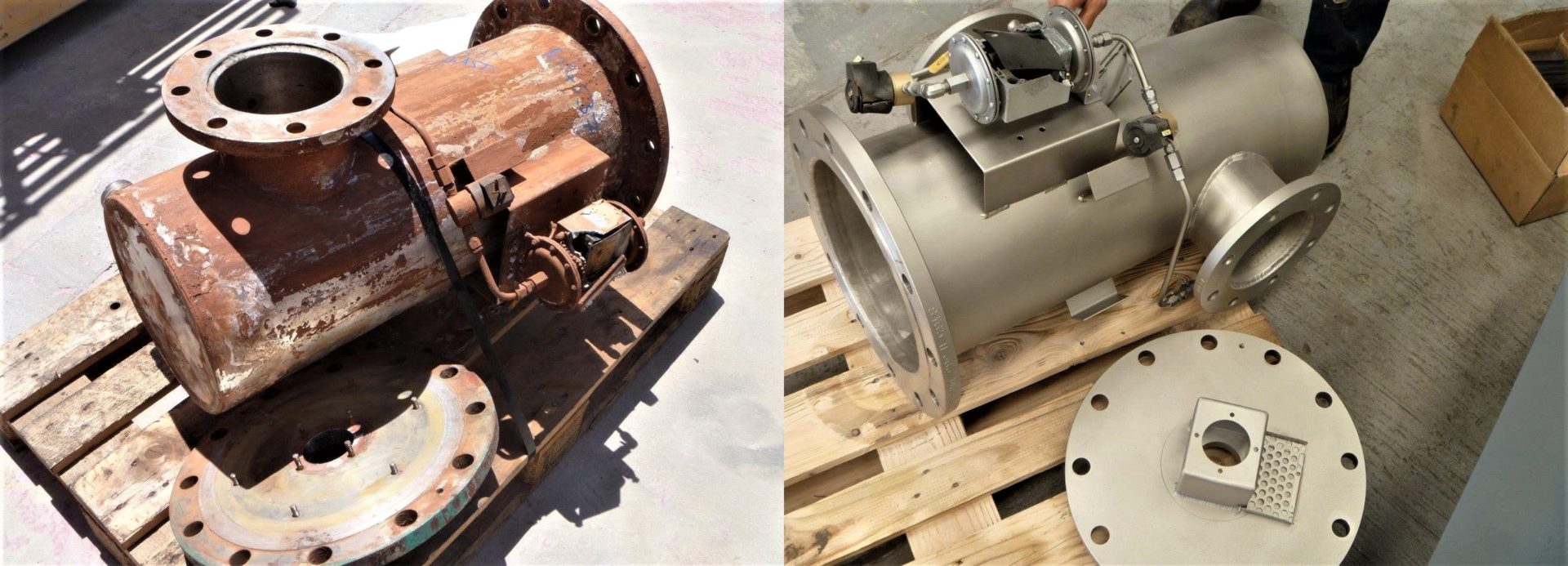

Blasting is renowned for its effectiveness; it can clean dirt and debris thoroughly, while also grinding rust, paint, and corrosion from metal surfaces to result in the best possible finish.

- Sandblasting is a great way to remove rust, oil, and harmful contaminants from almost any kind of surface.

- Quick—Sandblasting is extremely efficient and makes cleaning metal and other tough surfaces

- Removes old paint and prepares for new coatings

Professional Sand Blasting

- Proper equipment is required to safely sandblast.

- The proper safety precautions are required for safe sandblasting.

Uses for Sand Blasting

In the past, silica sand was one of the most common abrasives used. Garnet Blasting has now replaced silica sand as a much more healthy and environmentally friendly media for abrasive blasting.

Depending on the environmental conditions, the surface preparation required, we offer a range of options.

- Garnet Blasting

- Soda Blasting

- Shot Blasting

- Grit Blasting

- Glass Bead Blasting

- Whip Blasting

- Dry Blasting

- High Pressure Blasting